Choosing the right crusher is crucial for any construction or mining project. The correct type ensures efficient and effective material processing. Different materials require specific crushers to achieve the best results. This guide will help you navigate the options available for stone crusher, aggregate crusher, gravel crusher, and granite crusher applications.

Understanding Crusher Types

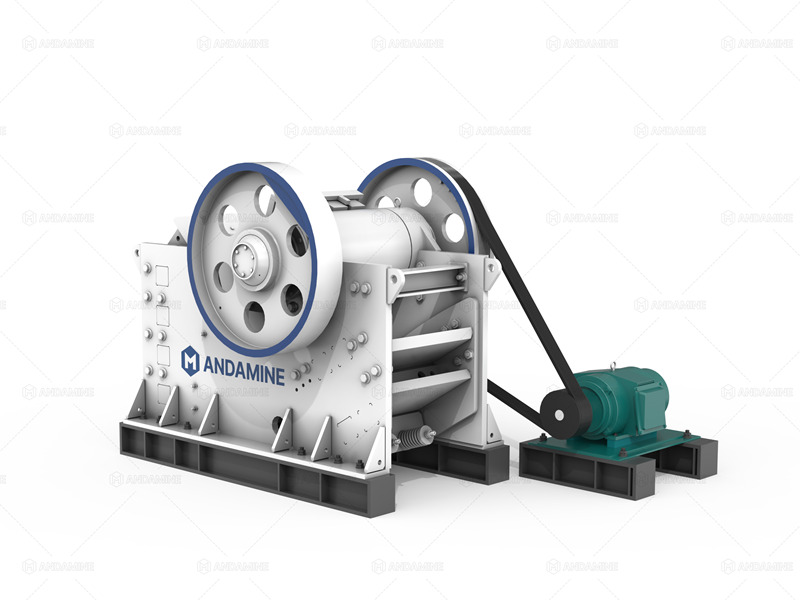

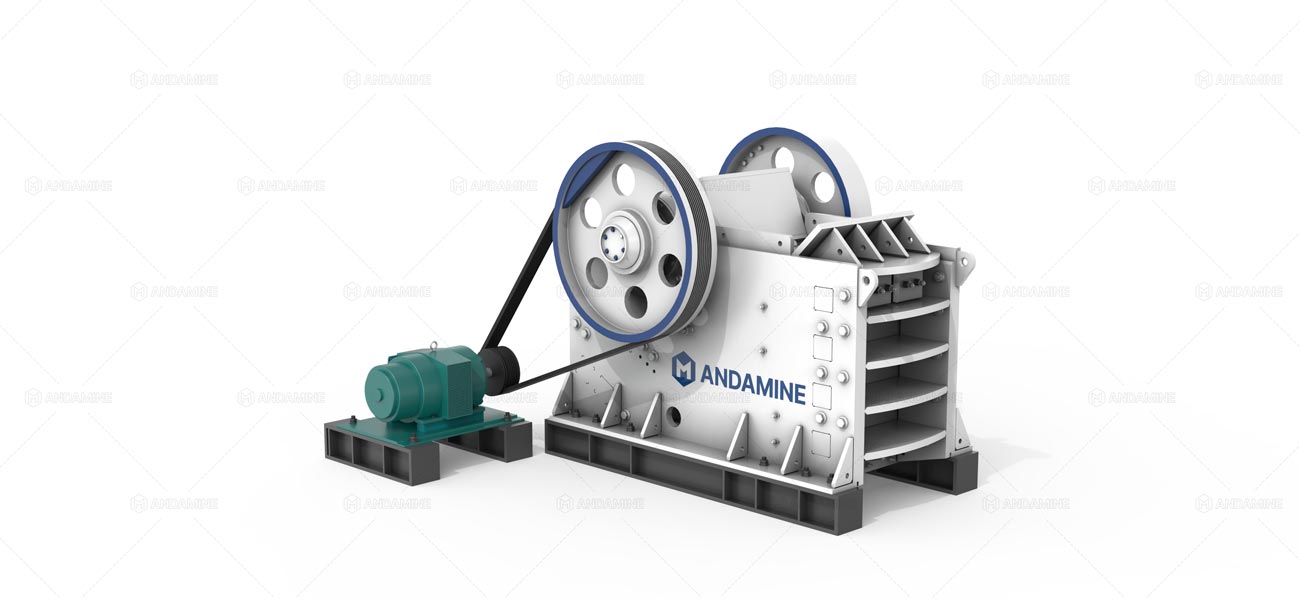

There are several types of crushers, each designed for specific materials. Understanding their functions enhances decision-making. The primary categories include jaw crushers, cone crushers, impact crushers, and gyratory crushers. Each type has unique features tailored for different materials and processing needs.

Stone Crusher Selection

Stone crushers are versatile machines used to crush various stones. For softer stones like limestone, consider using impact crushers. They provide efficient size reduction with minimal fines. For harder stones such as basalt, jaw crushers or gyratory crushers work best. They offer high crushing efficiency and durability.

Aggregate Crusher Choices

Aggregates are essential in construction projects. Choosing the right aggregate crusher impacts the quality of the final product. Cone crushers are ideal for producing high-quality aggregates. They offer precise control over particle size and shape. For larger aggregate sizes, jaw crushers provide the necessary power and efficiency.

Gravel Crusher Options

Gravel crusher is crucial for producing road base materials. Impact crushers are effective for creating fine gravel. They excel at processing softer materials. However, for coarser gravel, jaw crushers offer better performance. They efficiently handle larger feed sizes and produce uniform outputs.

Granite Crusher Considerations

Granite is a hard and abrasive material. Choosing the right granite crusher is vital for success. Cone crushers are excellent for granite. They provide high reduction ratios and consistent outputs. Alternatively, jaw crushers can also handle granite. They offer robust performance and durability for demanding tasks.

Factors Influencing Crusher Selection

Several factors influence the choice of crusher type. First, consider the material’s hardness and abrasiveness. Harder materials require stronger crushers. Second, evaluate the desired output size and shape. Different crushers produce varying particle sizes and shapes. Third, assess the production capacity needed. Larger projects demand crushers with higher throughput.

Environmental and Operational Considerations

Environmental factors also play a role in crusher selection. Dust and noise emissions may impact your choice. Opt for crushers with dust suppression features if needed. Additionally, consider the operational environment. Mobile crushers offer flexibility for remote locations. They are easily transported and set up on-site.

Cost and Maintenance Aspects

Cost is another critical factor. While high-end crushers may offer better performance, they come with a higher price tag. Balance initial investment with long-term benefits. Maintenance requirements vary between crusher types. Consider ease of maintenance and availability of spare parts. Regular maintenance ensures optimal performance and longevity.

Conclusion

In conclusion, choosing the right crusher type for different materials involves careful consideration. Understanding the unique requirements of stone crushers, aggregate crushers, gravel crushers, and granite crushers is essential. Factors like material hardness, desired output, environmental conditions, and cost influence the decision. By evaluating these aspects, you can select the most suitable crusher for your needs. This ensures efficient processing and high-quality end products. Investing time in choosing the right crusher pays off in the long run. It enhances productivity and reduces operational costs.